How On-Site Inspections Help Identify Hidden Safety and Performance Issues

February 20, 2026

In today’s industrial and manufacturing landscape, maintaining safety and performance standards is more critical than ever. Hidden issues, often undetectable through routine checks or remote monitoring, can escalate into significant operational challenges, posing risks to both personnel and equipment. On-site inspections serve as a proactive approach, offering a firsthand view of facilities, machinery, and processes. By conducting thorough, in-person evaluations, companies can identify vulnerabilities, inefficiencies, and potential hazards that may otherwise go unnoticed. The ability to detect these concerns early can prevent costly downtime, enhance workplace safety, and extend the lifespan of equipment. Moreover, early identification of risks enables better resource allocation, reducing long-term maintenance costs and improving operational efficiency across all departments.

The relevance of on-site inspections extends across industries—from manufacturing plants to construction sites, commercial facilities to metal fabrication shops. While technology and data analytics provide valuable insights, nothing can fully replace the nuanced assessment achieved through physical presence. Observing operational workflows, environmental conditions, and equipment performance in real time allows inspectors to evaluate risks with precision. Understanding how hidden issues manifest, whether as subtle structural weaknesses or minor process deviations, empowers organizations to implement targeted solutions. Ultimately, consistent on-site inspections are not merely a compliance exercise but a strategic tool that strengthens safety culture, ensures operational excellence, and supports sustainable business growth. This proactive approach also fosters employee confidence, demonstrating a company’s commitment to a safe and reliable work environment while protecting long-term profitability.

Understanding On-Site Inspections

What Are On-Site Inspections?

On-site inspections involve a detailed, physical assessment of a facility, structure, or piece of equipment by qualified personnel with specialized training and expertise. Unlike remote monitoring or routine visual checks, these inspections are comprehensive and include close examination of operational systems, safety measures, and structural integrity to uncover subtle hidden risks. Inspectors may use specialized tools such as thermal cameras, vibration sensors, or ultrasonic devices to detect defects that are often invisible to standard evaluations. This hands-on approach provides a level of detail unattainable through automated systems alone, ensuring that no minor irregularity goes unnoticed.

The Importance of Physical Presence

The presence of an experienced inspector allows for real-time evaluation of conditions, interactions, and workflow inefficiencies that could affect safety and operational performance. Observers can identify issues like worn components, misaligned machinery, or subtle environmental hazards—problems that may not trigger automated alerts or routine maintenance checks. Moreover, the human element is crucial for understanding operational context, behavioral patterns, and process nuances that directly influence both safety and performance metrics over time.

Real-World Example

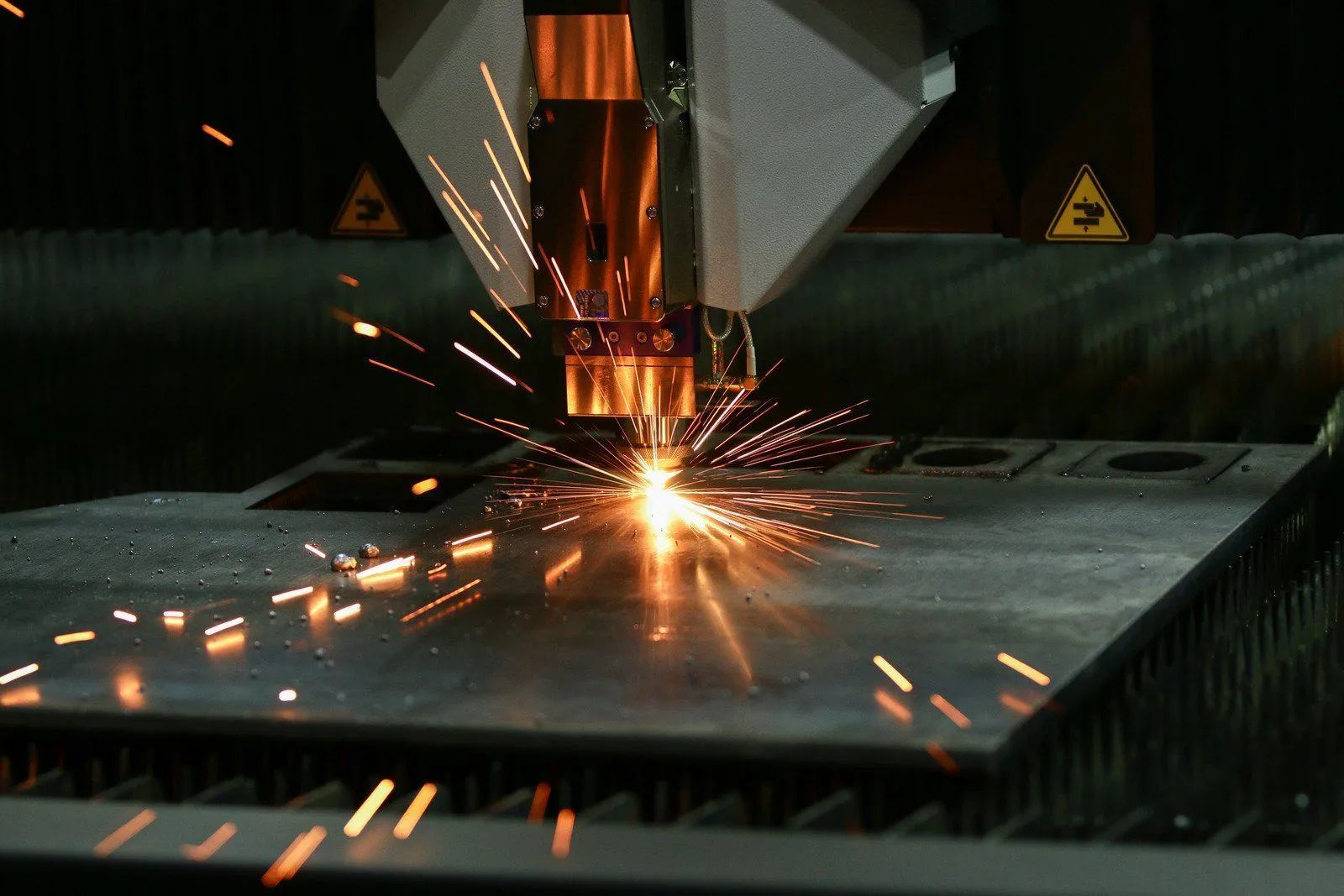

In a metal fabrication plant, for instance, an on-site inspector may notice unusual wear on a press machine or minor corrosion on a critical joint—issues that could escalate into equipment failure if left unaddressed. These early observations enable timely maintenance, process adjustments, and preventive interventions, ultimately preventing costly repairs, operational downtime, or safety incidents. This example demonstrates the tangible and measurable value of thorough physical inspections in industrial environments.

Identifying Hidden Safety Hazards

Common Hidden Risks in Industrial Settings

Even well-maintained facilities can harbor hidden hazards that develop gradually over time and may remain unnoticed until an incident occurs. These include structural weaknesses, electrical inconsistencies, chemical exposure risks, or unsafe machinery operation conditions. Many of these threats develop incrementally, making them difficult to detect without a detailed, on-site examination that considers operational patterns, material integrity, and environmental influences on equipment performance.

Techniques for Detection

Effective inspections often involve multiple complementary approaches:

- Visual Assessment: Checking for cracks, rust, leaks, misalignments, and subtle deterioration over time.

- Operational Testing: Running equipment to observe irregularities, abnormal noises, or performance inconsistencies.

- Environmental Monitoring: Measuring temperature, humidity, or airborne particulates that could negatively impact safety.

- Safety Compliance Checks: Ensuring guards, emergency exits, signage, and personal protective equipment meet regulatory standards.

Benefits of Early Hazard Detection

Detecting hazards before they escalate prevents injuries, reduces downtime, and avoids regulatory penalties that can disrupt operations. For example, identifying an unstable scaffold during a site inspection can prevent serious falls, while uncovering faulty wiring may avert fire risks or equipment damage. These proactive measures protect employees, preserve operational continuity, and safeguard the organization’s reputation, reinforcing a long-term culture of safety and responsibility throughout the facility.

Enhancing Performance Through Inspections

How Hidden Issues Affect Efficiency

Performance issues often remain concealed until they begin to significantly impact productivity, quality, or operational costs. Misaligned machinery, inefficient workflows, or unnoticed equipment wear can reduce output, increase energy consumption, and generate higher maintenance expenses over time. On-site inspections provide precise insight into these hidden inefficiencies, offering actionable opportunities to optimize processes, improve equipment reliability, and enhance overall operational performance.

Tools and Methods for Performance Assessment

Inspectors may use a combination of hands-on and analytical tools:

- Data-Driven Analysis: Combining on-site observations with production data to pinpoint bottlenecks and recurring inefficiencies.

- Maintenance Logs Review: Evaluating historical records to anticipate recurring issues and predict future maintenance needs.

- Hands-On Testing: Conducting functional tests to measure machine performance against operational standards and tolerances.

Best Practices for Effective On-Site Inspections

Planning and Preparation

Effective inspections begin with strategic planning and thorough preparation to maximize accuracy and outcomes. Inspectors should define clear objectives, understand facility layout, identify high-risk areas, and anticipate potential hazards before visiting the site. Pre-inspection documentation, including equipment manuals, previous inspection reports, operational protocols, and safety guidelines, provides essential context that ensures evaluations are both efficient and highly effective.

Engaging Skilled Personnel

The expertise of the inspection team significantly influences the accuracy and reliability of findings. Trained inspectors bring knowledge of industry standards, regulatory compliance, and operational best practices, enabling them to recognize subtle signs of risk that less experienced personnel might overlook. Skilled evaluators also contribute recommendations for preventive measures and corrective actions, enhancing both safety and productivity.

Documentation and Reporting

Comprehensive reporting is critical for converting observations into actionable improvements. Detailed records, annotated photographs, diagrams, and descriptive notes ensure that findings are clearly communicated to maintenance and management teams. Clear documentation allows corrective actions to be implemented efficiently, establishes accountability, and provides a reference for subsequent inspections, supporting a cycle of continuous improvement.

Follow-Up Actions

Inspections are only valuable when followed by proactive and systematic actions. Prioritizing issues based on severity, developing structured maintenance schedules, and monitoring the implementation of corrective measures ensures long-term safety, operational reliability, and performance improvement across the facility. Without follow-up, even the most detailed inspections risk being ineffective or overlooked.

Overcoming Challenges in On-Site Inspections

Common Obstacles

While invaluable, on-site inspections can face challenges such as limited accessibility, interference with production, or incomplete historical data that reduces context. Environmental factors like poor lighting, high noise levels, or hazardous conditions may also hinder accurate assessment and measurement, potentially limiting the inspector’s ability to fully evaluate equipment or structural integrity.

Solutions and Mitigation Strategies

- Scheduling Flexibility: Conduct inspections during planned downtime or off-peak hours to minimize operational disruption.

- Advanced Technology: Employ drones, sensors, thermal imaging, or portable testing equipment to safely access difficult or hazardous areas.

- Collaboration: Coordinate with facility managers, operators, and staff to gather operational insights and streamline the inspection process efficiently.

Maximizing Value From Inspections

Strategic Integration

On-site inspections should not be treated as isolated events but as part of a comprehensive safety, performance, and operational strategy. Integrating inspections with preventive maintenance programs, employee training initiatives, and operational audits ensures that findings translate into meaningful improvements and long-term operational resilience.

Employee Involvement

Involving employees in the inspection process fosters accountability, ownership, and heightened awareness of safety and performance standards. Workers often possess firsthand knowledge of recurring issues, operational challenges, and equipment quirks, contributing valuable context that improves accuracy and effectiveness of inspections.

Continuous Improvement

Inspections create opportunities for ongoing improvement and long-term operational excellence. Regular evaluation cycles allow organizations to track progress, identify emerging risks, optimize workflows, and implement preventive solutions proactively. This structured approach strengthens resilience, enhances safety culture, and supports sustainable operational performance over time.

Reliable Metal Fabrication Experts Maximizing Performance Outcomes

On-site inspections are a critical tool for uncovering hidden safety and performance issues. By combining skilled observation, advanced technology, and systematic evaluation, organizations gain a comprehensive understanding of their operational environment. Early detection of hazards prevents accidents and costly downtime, while addressing performance inefficiencies improves productivity and operational reliability. Strategic planning, skilled personnel, and continuous follow-up are essential to maximizing the value of inspections. Real-world examples across industrial and manufacturing settings demonstrate that proactive, hands-on evaluations significantly enhance safety culture and operational performance.

At Associated Metal Works, we understand the importance of meticulous on-site inspections for maintaining both safety and efficiency. With over 40

years of experience as a trusted metal fabricator in North Carolina, we have built our reputation on precision, reliability, and operational excellence. Our team conducts thorough evaluations of fabrication processes, structural integrity, and equipment performance to identify potential risks before they escalate. By combining decades of expertise with advanced inspection techniques, we help clients implement proactive solutions that minimize downtime, enhance safety, and optimize production outcomes. Choosing Associated Metal Works

means partnering with an experienced authority dedicated to protecting both people and operations while delivering unmatched quality in metal fabrication. Our commitment to comprehensive inspections and actionable insights ensures every project meets the highest safety and performance standards, reinforcing trust and confidence across every client engagement.