Why Industrial Material Handling Fans are Essential for Manufacturing Efficiency

November 24, 2025

In modern manufacturing facilities, maintaining a safe, efficient, and productive work environment is critical. One often overlooked but essential tool in achieving this is industrial material handling fans. These fans are designed to optimize airflow, regulate temperature, and manage airborne particles, contributing directly to operational efficiency. They not only protect sensitive machinery from overheating but also improve worker comfort and safety. By controlling dust, fumes, and excess heat, industrial fans help prevent production delays and maintain consistent product quality. For manufacturers seeking to reduce downtime and energy costs, investing in high-quality fans is a smart, long-term solution that supports sustainable operations and overall facility performance.

Improved Air Circulation and Temperature Control

One of the primary benefits of industrial material handling fans is their ability to improve air circulation. Proper airflow ensures that machinery does not overheat, which can lead to malfunctions, reduced equipment lifespan, and costly repairs. By maintaining consistent temperatures, these fans help optimize machine performance and minimize unexpected shutdowns. Furthermore, regulated air circulation creates a more comfortable environment for workers, enhancing focus and productivity across the production floor.

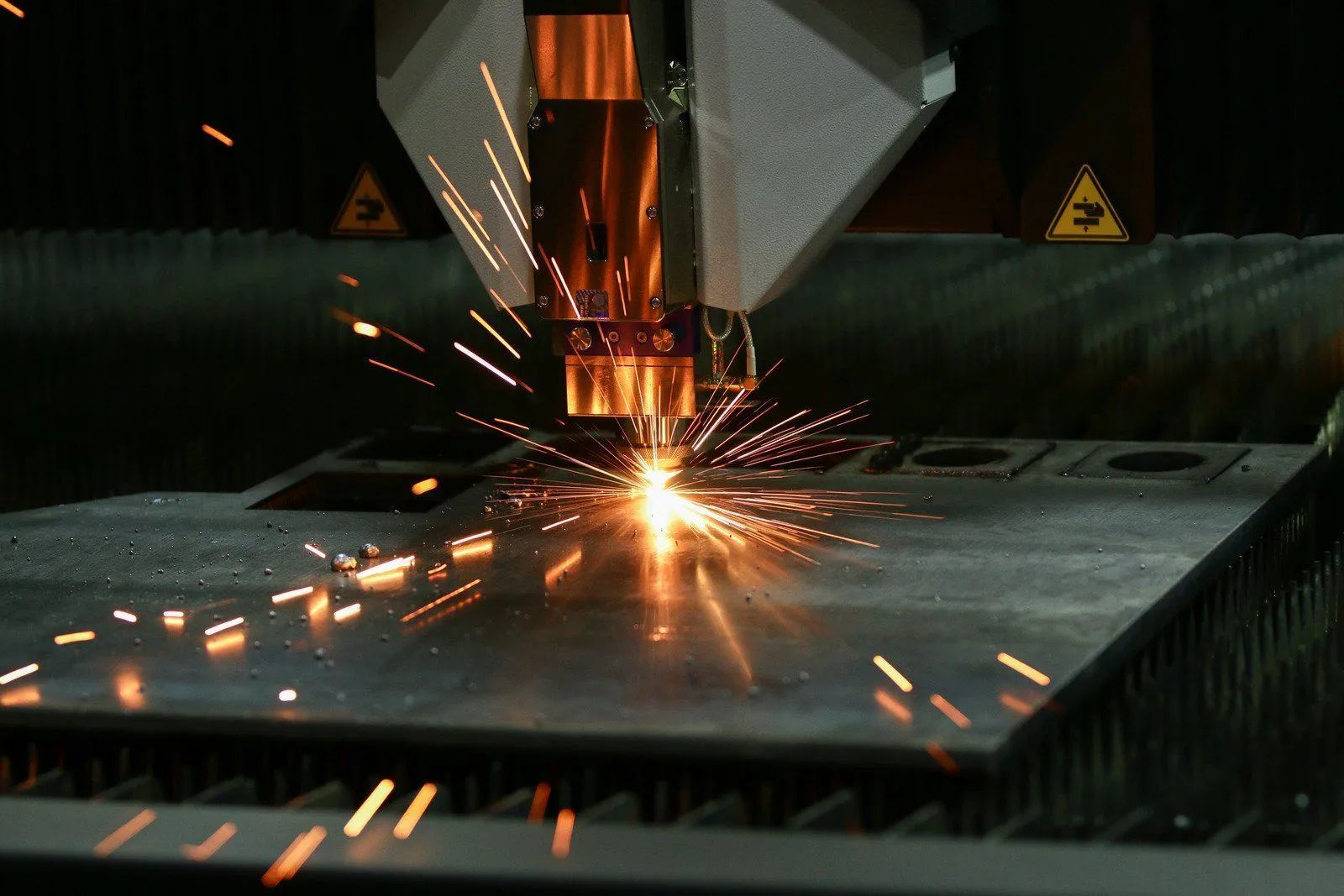

Effective Dust and Particle Management

Manufacturing processes, particularly in metal fabrication, often produce fine dust, fumes, and debris that can compromise both worker safety and product quality. Industrial fans help capture and move these airborne particles, preventing accumulation and reducing the risk of respiratory hazards. Cleaner air also minimizes contamination of sensitive products, maintaining high-quality standards. By integrating fans into dust collection and ventilation systems, facilities can achieve a healthier workspace and ensure compliance with safety regulations.

Energy Efficiency and Cost Savings

Modern industrial fans are designed with energy efficiency in mind. By optimizing airflow and minimizing the need for excessive cooling systems, these fans help reduce energy consumption and operational costs. Efficient fans can circulate air more effectively at lower power levels, ensuring that manufacturing facilities remain sustainable while cutting utility expenses. Over time, the reduction in maintenance, energy usage, and downtime can translate into substantial financial savings for the business.

Supporting Specialized Manufacturing Needs

Different manufacturing processes require tailored airflow solutions. Industrial material handling fans come in a variety of designs, including high-velocity, centrifugal, and axial models, to meet specific operational needs. Whether it’s removing heat from heavy machinery, controlling fumes from welding operations, or ventilating confined spaces, these fans provide customized solutions that enhance efficiency and safety across diverse industrial applications.

Reliable Fans and Fabrication for Maximum Productivity

For over 40 years, Associated Metal Works, based in North Carolina, has been a leading provider of high-quality metal fabrication solutions, including industrial material handling systems. Their expertise in designing and supplying durable, efficient fans ensures that manufacturing facilities can maintain optimal airflow, temperature control, and safety standards. By choosing Associated Metal Works, manufacturers gain access to decades of experience, reliable products, and innovative solutions that enhance operational efficiency. For any metal fabrication or industrial airflow needs, Associated Metal Works stands as a trusted partner committed to performance and longevity in North Carolina and beyond.