Precision and Efficiency: The Advantages of CNC and Laser Cutting for Industrial Applications

January 21, 2026

In today’s fast-paced industrial landscape, precision and efficiency are no longer optional—they are essential. Companies across the manufacturing, automotive, aerospace, and electronics sectors continually seek ways to optimize production while maintaining high-quality standards. Cutting technologies have evolved dramatically over the past few decades, transitioning from manual methods to highly advanced automated processes. Among these, CNC (Computer Numerical Control) and laser cutting have emerged as pivotal tools, transforming how industries approach material fabrication. Their ability to deliver precise, repeatable, and intricate cuts has revolutionized workflows, allowing manufacturers to produce components with exceptional accuracy while minimizing waste.

The relevance of CNC and laser cutting extends beyond precision; these technologies enhance overall operational efficiency. With automation at the core, businesses can reduce human error, shorten production timelines, and handle complex designs that would be nearly impossible with conventional tools. Furthermore, advancements in software integration allow for seamless coordination between design and production, ensuring that every cut aligns perfectly with engineering specifications. For industries striving to meet high-volume demands without compromising quality, understanding the advantages and practical applications of CNC and laser cutting is crucial. This knowledge enables companies to invest in the right technology while achieving optimal productivity, cost-effectiveness, and superior product outcomes.

The Fundamentals of CNC and Laser Cutting

Understanding CNC Cutting

CNC cutting relies on computer-controlled machinery to execute pre-programmed sequences for material removal or shaping. Unlike traditional manual methods, CNC systems use digital designs to guide cutting tools along precise paths. This ensures consistent dimensions, tight tolerances, and uniformity across multiple production runs. CNC technology is compatible with various materials, including metals, plastics, wood, and composites, making it versatile across industrial applications.

Key Components of CNC Systems

- Controller Software: Translates CAD (Computer-Aided Design) files into machine-readable instructions.

- Cutting Tools: Vary depending on material and desired outcomes, including mills, routers, and plasma torches.

- Motion Systems: Ensure smooth and accurate movement of the tool along X, Y, and Z axes.

By automating complex operations, CNC cutting minimizes the need for manual adjustments, allowing engineers to focus on design optimization rather than repetitive tasks.

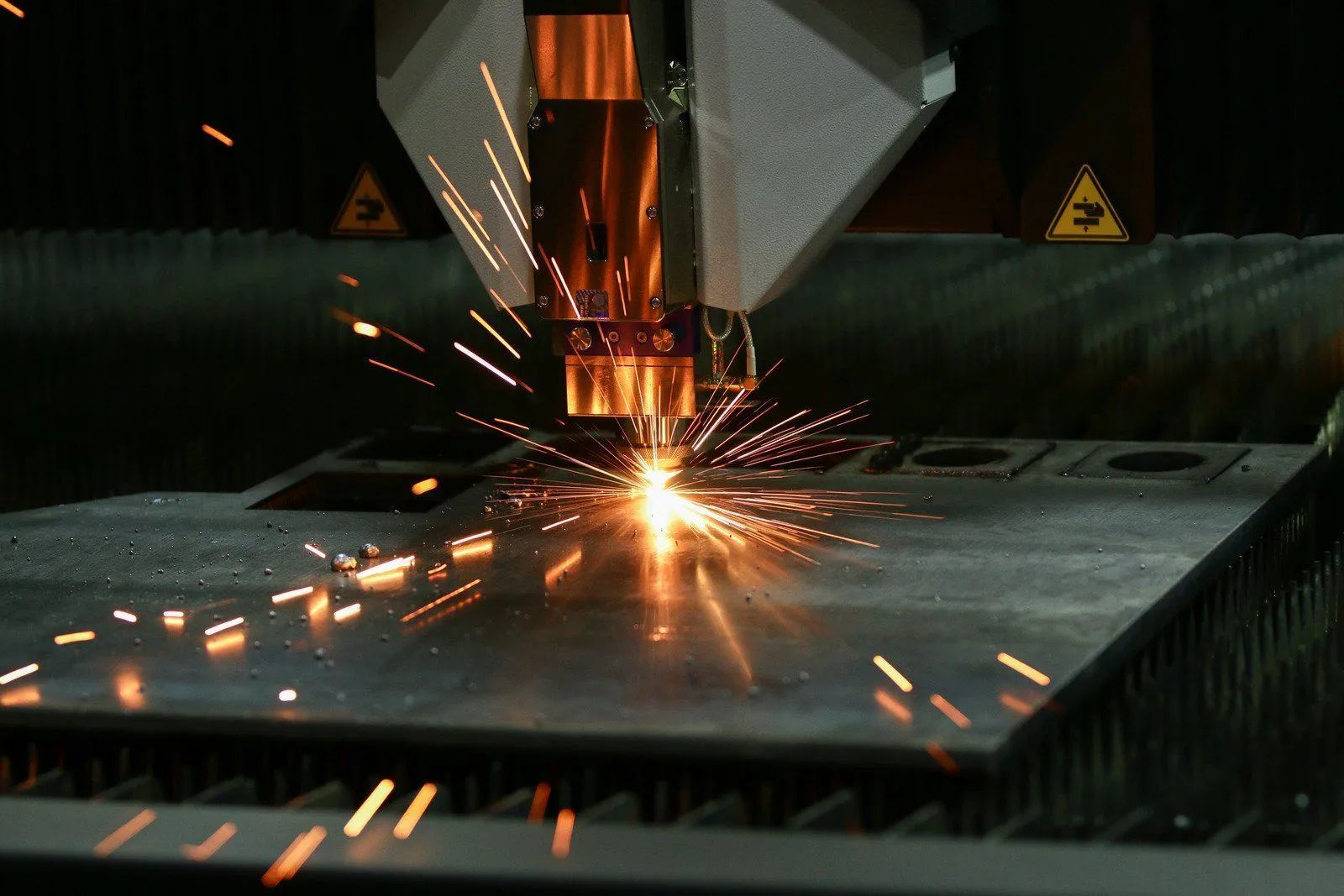

Laser Cutting Explained

Laser cutting, on the other hand, uses a concentrated beam of light to cut or engrave materials with remarkable precision. The laser melts, burns, or vaporizes the target area, producing clean edges and intricate patterns without physical contact. This non-contact method significantly reduces mechanical stress on materials and lowers the risk of warping or deformation.

Advantages of Laser Technology

- High Precision: Capable of achieving tolerances as low as ±0.1 mm.

- Versatility: Effective on metals, plastics, ceramics, and even certain fabrics.

- Speed: Rapid processing for both single pieces and mass production runs.

Industries such as aerospace, medical device manufacturing, and electronics benefit greatly from the fine detail and smooth finishes achievable with laser cutting, often exceeding the capabilities of conventional methods.

Industrial Benefits of CNC and Laser Cutting

Enhanced Precision and Consistency

Precision is a critical factor in industrial manufacturing, where even minor deviations can compromise product integrity. CNC and laser cutting technologies excel in delivering high levels of accuracy. For instance, aerospace components require tight tolerances to ensure safety and functionality. CNC machines can execute repeated operations with near-zero variation, while laser cutters produce flawless edges and intricate patterns without additional finishing.

Real-World Example: Automotive manufacturers use laser cutting to produce complex metal panels and engine components. The consistent quality reduces rework and material wastage, directly impacting cost efficiency.

Increased Production Speed

Efficiency in manufacturing is often measured by the speed of production without sacrificing quality. CNC and laser cutting systems operate at high speeds, handling both simple and complex designs efficiently. Automation eliminates downtime associated with manual adjustments, allowing continuous operation.

Expert Insight: Factories integrating CNC and laser cutting report up to a 40% reduction in production cycle times compared to traditional methods. This increased throughput translates into faster delivery schedules and improved competitiveness in the market.

Material Optimization and Waste Reduction

Both CNC and laser cutting technologies contribute to sustainable manufacturing practices by minimizing material waste. Advanced software calculates optimal cutting paths to use materials effectively, reducing scrap and lowering overall production costs.

Practical Example: Sheet metal fabrication often results in leftover offcuts. Laser cutting software nests designs efficiently, ensuring maximum material utilization while maintaining precise tolerances.

Versatility Across Applications

Industrial operations require adaptable solutions to handle diverse materials and product designs. CNC machines can switch between milling, drilling, and routing tasks, while laser cutters excel in engraving, perforating, and high-precision slicing. This versatility allows manufacturers to meet varied client requirements without investing in multiple specialized tools.

Industry Insight: Electronics manufacturers use laser cutting for circuit boards and micro-components, while CNC machines shape housings, connectors, and structural parts—all from the same production floor.

Challenges and Considerations in CNC and Laser Cutting

Initial Investment and Maintenance

While CNC and laser cutting offer long-term advantages, they require significant upfront investment. High-precision machinery, quality software, and skilled operators come at a premium. Additionally, maintenance is crucial to prevent downtime and maintain accuracy.

Best Practice: Investing in preventive maintenance schedules and training operators can extend machine life and ensure consistent production quality.

Skill Requirements and Training

Operating CNC and laser systems requires technical knowledge. Staff must understand CAD/CAM software, machine calibration, and material properties to maximize efficiency. Improper use can lead to errors, wasted material, and reduced equipment lifespan.

Expert Recommendation: Continuous employee training programs and certifications help companies stay current with evolving technologies and industry standards.

Limitations in Material Thickness and Type

Although versatile, both CNC and laser cutting have material-specific limitations. Very thick metals may require slower laser cutting speeds or additional passes, and certain reflective surfaces can interfere with laser efficiency. CNC tools, while adaptable, may require different tooling setups for hard metals versus softer materials.

Practical Tip: Evaluating material properties before selecting the cutting method ensures the process is both effective and economical.

Integration with Modern Manufacturing Systems

Automation and Industry 4.0

CNC and laser cutting systems integrate seamlessly with Industry 4.0 technologies, including IoT sensors, cloud-based monitoring, and automated workflow management. This connectivity allows real-time performance tracking, predictive maintenance, and data-driven production optimization.

Example:

Smart factories use CNC machines linked to central software systems to monitor tool wear, predict downtime, and adjust cutting parameters dynamically, reducing unexpected interruptions.

Software-Driven Design Precision

Modern CAD/CAM software enhances both CNC and laser cutting capabilities by generating optimized tool paths, simulating production runs, and detecting potential errors before actual cutting begins. This reduces material waste and improves first-pass success rates.

Practical Insight: Aerospace companies rely on software simulations to validate complex geometries, ensuring that critical components meet strict regulatory and safety standards.

Scalability for High-Volume Production

CNC and laser cutting systems are highly scalable, accommodating both small-batch prototypes and mass production runs. Automated material handling, multi-axis cutting, and programmable setups enable manufacturers to scale operations efficiently without compromising precision.

Case Study: Consumer electronics manufacturers often use a combination of CNC milling for structural components and laser cutting for intricate circuit board patterns, allowing rapid prototyping and large-scale production within the same facility.

Enhancing Product Quality and Design Flexibility

Complex Geometries Made Simple

One of the standout advantages of CNC and laser cutting is the ability to produce intricate shapes and designs that traditional cutting methods cannot achieve. Curved edges, fine engravings, and multi-layered assemblies can all be executed with minimal post-processing.

Industrial Example: Medical device manufacturers use laser cutting to create surgical tools and implants with highly detailed geometries, ensuring both functional performance and biocompatibility.

Minimal Post-Processing Requirements

Because CNC and laser cutting deliver precise edges and smooth surfaces, the need for secondary finishing operations such as grinding, polishing, or sanding is significantly reduced. This not only shortens production timelines but also reduces labor costs and the risk of introducing defects.

Expert Insight: Reduced post-processing is particularly valuable in high-precision industries like aerospace and electronics, where surface quality directly impacts product performance.

Customization and Prototyping

CNC and laser cutting technologies allow rapid prototyping and easy customization of designs, enabling manufacturers to adapt quickly to market demands or client specifications. This agility is critical for industries that rely on iterative design improvements and personalized products.

Practical Application: Automotive aftermarket companies leverage CNC and laser cutting to produce custom components, from personalized dashboards to tailored metal trims, meeting client-specific design requests efficiently.

Maximizing Industrial Efficiency Through Advanced Cutting Techniques

CNC and laser cutting have transformed industrial manufacturing by enabling precision, consistency, and efficiency across a wide range of applications. Their ability to handle complex geometries, minimize waste, and accelerate production timelines makes them indispensable in sectors requiring high-quality outputs. When implemented with the right combination of skilled operators, advanced software, and maintenance strategies, these technologies unlock significant operational and financial benefits.

At Associated Metal Works, based in North Carolina, we bring over 40

years of experience in advanced metal fabrication and industrial cutting solutions. Our team leverages state-of-the-art CNC and laser cutting technologies to deliver superior precision and efficiency, catering to industries with demanding quality standards. Committed to excellence, we ensure every project meets exact specifications while optimizing material use and reducing production timelines. Clients trust Associated Metal Works

for dependable, high-quality services backed by decades of expertise and a deep understanding of modern manufacturing needs.