Understanding the Benefits of Professional Rotary Valves in Bulk Material Processing

December 22, 2025

Being locked out of your car is an inconvenience that can disrupt your entire day. Whether it happens during a busy workday, a late-night errand, or a family outing, a car lockout is more than just frustrating—it can also be stressful and potentially dangerous. The rise of advanced car security systems has made vehicles safer, but these same systems can make lockouts more complicated for drivers who are unprepared. Many car owners unknowingly make mistakes that worsen the situation, resulting in delays, increased costs, or even damage to their vehicles.

Understanding the most common car lockout mistakes and learning how to avoid them is essential for every driver. By recognizing the errors people often make, you can proactively take steps to prevent being stranded and handle lockout situations more effectively. This blog will explore six frequent car lockout mistakes, offering practical strategies, expert advice, and real-world examples to help drivers stay safe, save time, and protect their vehicles. Whether you are a new driver or an experienced car owner, implementing these insights will reduce the stress of lockouts and keep your daily routine on track.

Key Functions and Design of Rotary Valves

Fundamental Role in Bulk Material Handling

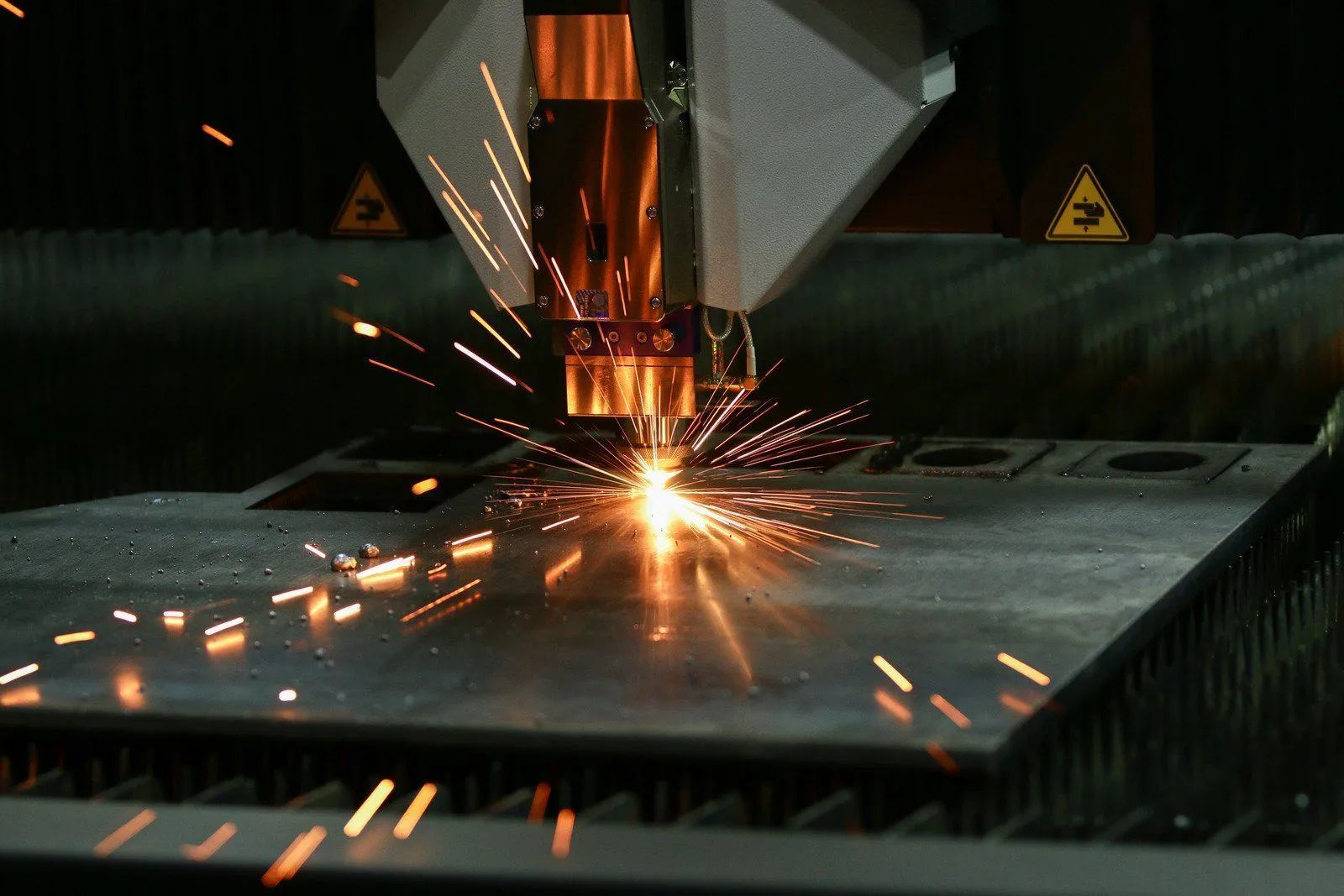

Rotary valves, also known as rotary airlocks or feeders, primarily serve to regulate the flow of bulk materials from one processing stage to another. These devices are designed to operate under gravity, conveying materials from hoppers, silos, or bins into downstream systems such as conveyors, mixers, or pneumatic transport lines. By providing a controlled discharge rate, rotary valves prevent material surges that could damage equipment or interrupt production.

For example, in a chemical processing plant, powders are often highly sensitive to dust contamination. A rotary valve not only facilitates consistent feeding but also maintains a seal between high-pressure pneumatic systems and low-pressure material sources, reducing the risk of dust emissions and ensuring compliance with environmental and safety regulations.

Design Elements and Material Considerations

Rotary valves are typically constructed from robust metals like stainless steel or cast iron, chosen for their durability and resistance to wear, corrosion, and abrasive materials. Key design elements include rotor type, rotor speed, housing configuration, and sealing mechanisms. Depending on the material’s characteristics—such as flowability, moisture content, and particle size—engineers may select a valve with tight clearances or specialized coatings to enhance performance and minimize wear.

Professional-grade valves often incorporate features like replaceable wear plates, abrasion-resistant rotors, and variable speed drives. These design considerations enable operators to adapt the system to a wide range of materials while extending service life and reducing operational downtime.

Operational Benefits of Professional Rotary Valves

Enhanced Flow Control and Accuracy

One of the primary advantages of rotary valves is their ability to provide precise control over material flow. In industries where consistency is critical—such as food or pharmaceutical manufacturing—maintaining uniform feed rates ensures that formulations remain accurate and products meet strict quality standards. By adjusting rotor speed or selecting a valve with an appropriate chamber volume, operators can regulate flow rates to match processing requirements exactly.

Minimized Dust and Contamination

Dust control is a major concern in bulk material handling, as airborne particles can pose health hazards, lead to equipment fouling, and create safety risks such as explosions in combustible environments. Professional rotary valves are engineered to form an airtight seal between material sources and processing equipment, significantly reducing dust emissions. For instance, in a flour milling facility, properly designed rotary valves prevent flour dust from escaping into the plant, protecting both workers and machinery.

Reduced Equipment Wear and Maintenance

Consistent and controlled feeding not only ensures product quality but also protects downstream equipment from excess wear. Sudden surges of material can overload conveyors, mixers, or pneumatic lines, leading to frequent maintenance requirements and costly repairs. By providing smooth and continuous material flow, rotary valves extend the lifespan of connected equipment and lower overall maintenance costs.

Versatility Across Materials and Industries

Rotary valves can handle a wide variety of bulk solids, including fine powders, granules, pellets, and abrasive materials. This versatility allows industries such as plastics, chemicals, cement, and food processing to employ a single technology for multiple applications. For example, a cement plant can use rotary valves for both clinker and powdered additives, while a food processing facility can manage grains and sugar through the same type of valve with minimal adjustments.

Real-World Applications and Case Studies

Food and Pharmaceutical Industries

In food processing plants, precise dosing of ingredients is critical. Rotary valves enable controlled feeding of flour, sugar, spices, or other powdered ingredients into mixers or packaging lines. Their ability to maintain airtight seals also helps prevent cross-contamination and complies with hygiene standards.

Similarly, in pharmaceutical manufacturing, rotary valves facilitate the accurate transfer of active ingredients or excipients into processing equipment. This ensures consistent batch quality while minimizing dust-related hazards. Variable-speed drives in professional valves allow operators to adjust feed rates for sensitive materials without causing segregation or clumping.

Chemical and Plastic Manufacturing

Chemical plants often handle abrasive powders and granules that can rapidly wear down standard valves. Using professional rotary valves with abrasion-resistant materials and replaceable wear parts allows these plants to maintain continuous operation while reducing downtime.

In plastics manufacturing, granules must be metered accurately into extruders or molding machines. Rotary valves provide precise volumetric feeding, preventing overfeeding or underfeeding that could compromise product quality. Their robust construction ensures that even high-throughput operations can run smoothly for extended periods.

Cement and Mineral Processing

Cement plants rely on rotary valves for controlled feeding of raw materials into kilns and grinders. By preventing surges and maintaining consistent flow, rotary valves help optimize combustion efficiency and reduce energy costs. Mineral processing operations benefit similarly, as rotary valves enable accurate handling of ores, sand, and other granular materials while protecting downstream screens and conveyors from excess wear.

Challenges in Rotary Valve Operation and Solutions

Handling Difficult Materials

Some bulk solids, such as sticky powders or irregularly shaped granules, can cause bridging or clogging in rotary valves. Professional-grade valves are often equipped with features like knife-edge rotors, adjustable clearances, or anti-bridging devices to mitigate these issues. Proper material characterization and valve selection are critical for addressing flow challenges.

Wear and Abrasion

High-abrasion materials like cement, sand, or certain chemicals can accelerate wear on rotors and housings. Using valves constructed with wear-resistant alloys, ceramic coatings, or replaceable liners can significantly extend operational life. Regular inspection and preventive maintenance also help identify wear patterns early, preventing costly breakdowns.

Energy Consumption

Rotary valves require motorized operation, which can contribute to overall energy costs. Selecting valves with efficient drive systems and optimizing rotor speeds based on material properties can minimize energy use while maintaining performance. Integration with automated process controls allows operators to balance energy efficiency with precise feeding requirements.

Ensuring Proper Sealing

Maintaining an airtight seal is essential for pneumatic conveying systems and dust control. Improper installation or worn components can compromise sealing performance. Professional installation, periodic inspection, and use of high-quality gaskets or packing materials ensure consistent operation and regulatory compliance.

Best Practices for Maximizing Rotary Valve Performance

Correct Valve Selection

Choosing the right rotary valve requires careful consideration of material characteristics, flow rate requirements, and operational environment. Factors such as particle size, moisture content, abrasiveness, and temperature must guide valve design selection. Consulting with experienced valve manufacturers ensures optimal performance and longevity.

Routine Maintenance and Monitoring

Even professional rotary valves require routine inspection and maintenance. Regular cleaning, lubrication, and monitoring of rotor clearances prevent wear and minimize downtime. Implementing predictive maintenance practices, such as vibration analysis or wear measurement, can further enhance reliability.

Integration with Process Controls

Modern facilities often use automated process controls to maintain optimal performance across bulk material handling systems. Integrating rotary valves with sensors, variable-speed drives, and PLCs enables real-time adjustments to feed rates, enhancing accuracy, energy efficiency, and overall process consistency.

Staff Training and Safety Protocols

Proper training for operators and maintenance personnel is essential. Understanding valve operation, troubleshooting common issues, and adhering to safety protocols ensures reliable performance while minimizing risk to personnel and equipment.

Driving Operational Success with Rotary Valve Solutions

The adoption of professional rotary valves in bulk material processing represents a strategic investment in efficiency, safety, and operational excellence. From controlling material flow and reducing wear to enhancing dust management and supporting automation, these devices deliver measurable benefits across a wide range of industries. Understanding their design, applications, challenges, and best practices equips operators, engineers, and facility managers to maximize performance while minimizing risk.

Associated Metal Works, based in North Carolina, brings over 40

years of expertise in designing, manufacturing, and supplying high-quality rotary valves for diverse bulk material handling applications. With decades of experience, the company has developed a reputation for delivering durable, efficient, and reliable solutions tailored to industry-specific needs. Their commitment to precision engineering, rigorous quality standards, and customer-focused service ensures that clients receive rotary valves optimized for performance, longevity, and safety. Whether for food processing, pharmaceuticals, chemicals, or cement operations, we combine decades of hands-on knowledge with cutting-edge manufacturing practices, providing peace of mind and operational excellence for every client. Partnering with a trusted authority like Associated Metal Works

guarantees not only a superior product but also expert guidance on installation, maintenance, and optimization, ensuring long-term success in bulk material processing systems.