The Role of Custom Metal Fabrication and Welding in Modern Industrial Projects

October 25, 2025

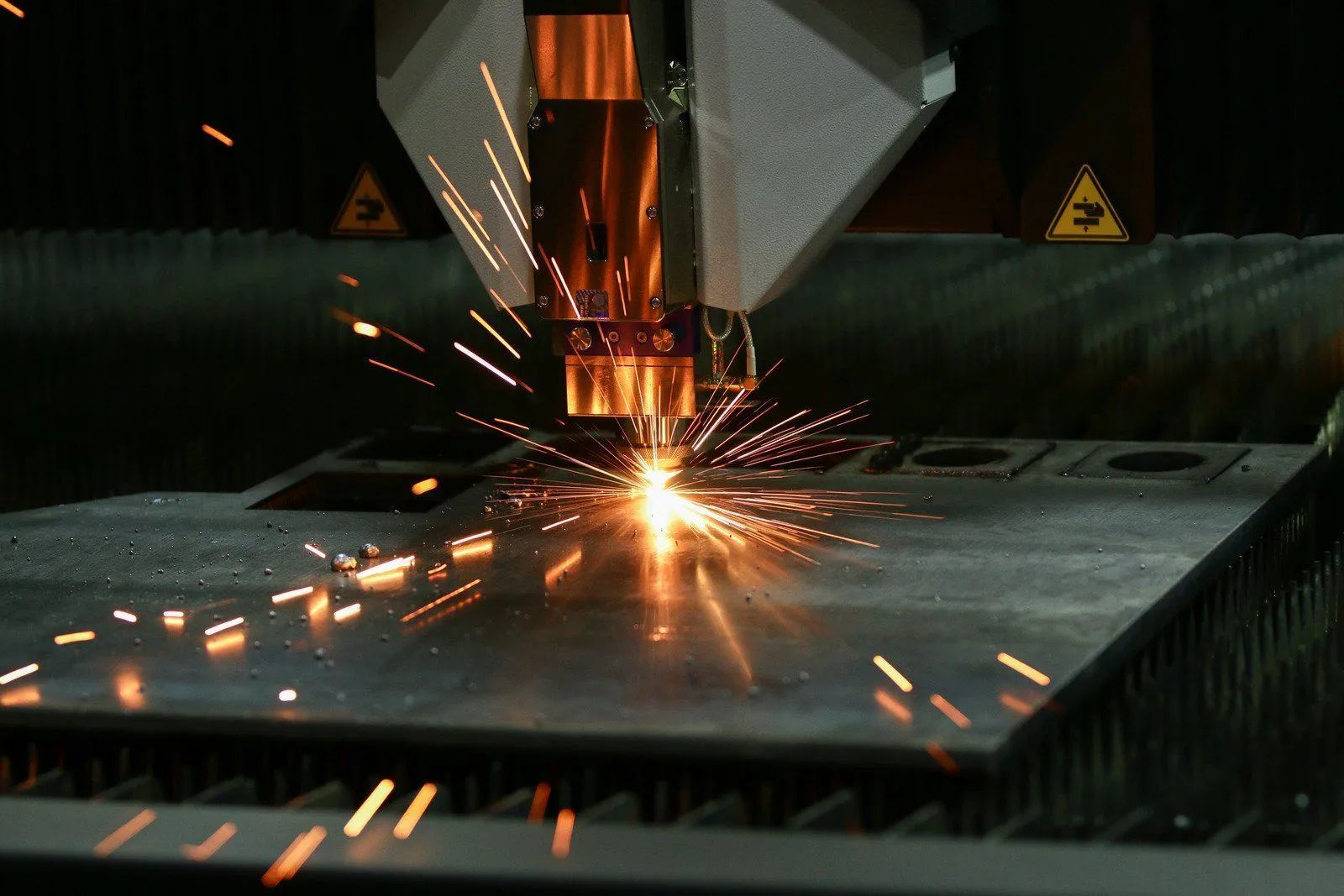

In today’s fast-paced industrial landscape, efficiency, precision, and innovation are more critical than ever. Custom metal fabrication and welding have become indispensable in achieving these goals, enabling industries to create complex structures, machinery, and components that meet exact specifications. From automotive and aerospace to construction and manufacturing, tailored metal solutions ensure durability, safety, and optimal performance. Modern projects demand more than standard materials—they require custom-designed metal components that fit perfectly within intricate systems. With advancements in technology, skilled metal fabricators and welders play a pivotal role in turning engineering concepts into tangible, high-quality results.

Precision Engineering for Complex Projects

Custom metal fabrication involves designing, cutting, shaping, and assembling metal components according to precise project requirements. Unlike mass-produced items, these custom solutions allow engineers and designers to address unique challenges, ensuring that every piece fits seamlessly into larger industrial systems. Welding, on the other hand, is the cornerstone of joining metal parts to create robust and reliable structures. Advanced welding techniques, including MIG, TIG, and robotic welding, provide the strength and precision needed for modern industrial applications.

Enhancing Efficiency and Reducing Waste

One significant advantage of custom metal fabrication is its ability to enhance efficiency. By producing components tailored to a project’s exact dimensions, fabrication reduces waste, minimizes installation time, and eliminates the need for extensive modifications on-site. This precision translates into faster project completion and lower overall costs, which is crucial for industries operating on tight schedules and budgets.

Ensuring Durability and Safety

Durability and safety are equally important. Industrial structures, from heavy machinery to storage tanks, must withstand immense pressure, extreme temperatures, and harsh environmental conditions. High-quality fabrication and welding ensure that these structures are not only structurally sound but also compliant with safety standards and regulations.

Supporting Innovation and Complex Designs

Custom metal fabrication also supports innovation. Industries seeking cutting-edge designs or specialized equipment often rely on metal fabricators to bring their concepts to life. With computer-aided design (CAD) software, laser cutting, and automated welding technologies, modern fabricators can produce intricate designs that were previously impossible or prohibitively expensive to manufacture. This combination of creativity and precision empowers industries to innovate while maintaining reliability.

Applications Across Industries

In sectors like renewable energy, transportation, and infrastructure, custom metal fabrication and welding enable the creation of specialized components such as turbine housings, custom vehicle frames, and architectural metalwork. By adapting to project-specific requirements, fabricators contribute directly to efficiency, sustainability, and long-term performance.

Trusted Expertise in Metal Fabrication

For over 40 years, Associated Metal Works, based in North Carolina, has been at the forefront of custom metal fabrication and welding, delivering high-quality solutions for a wide range of industrial projects. Our extensive experience, combined with skilled craftsmanship and modern technology, allows us to tackle complex projects with precision and reliability. Whether it’s fabricating intricate components, welding durable structures, or providing tailored solutions for specialized industries, Associated Metal Works ensures every project meets the highest standards of quality and safety. Trust our expertise to bring your industrial vision to life with excellence and innovation.