How Professional Dust and Fume Collection Systems Improve Workplace Air Quality and Safety

September 27, 2025

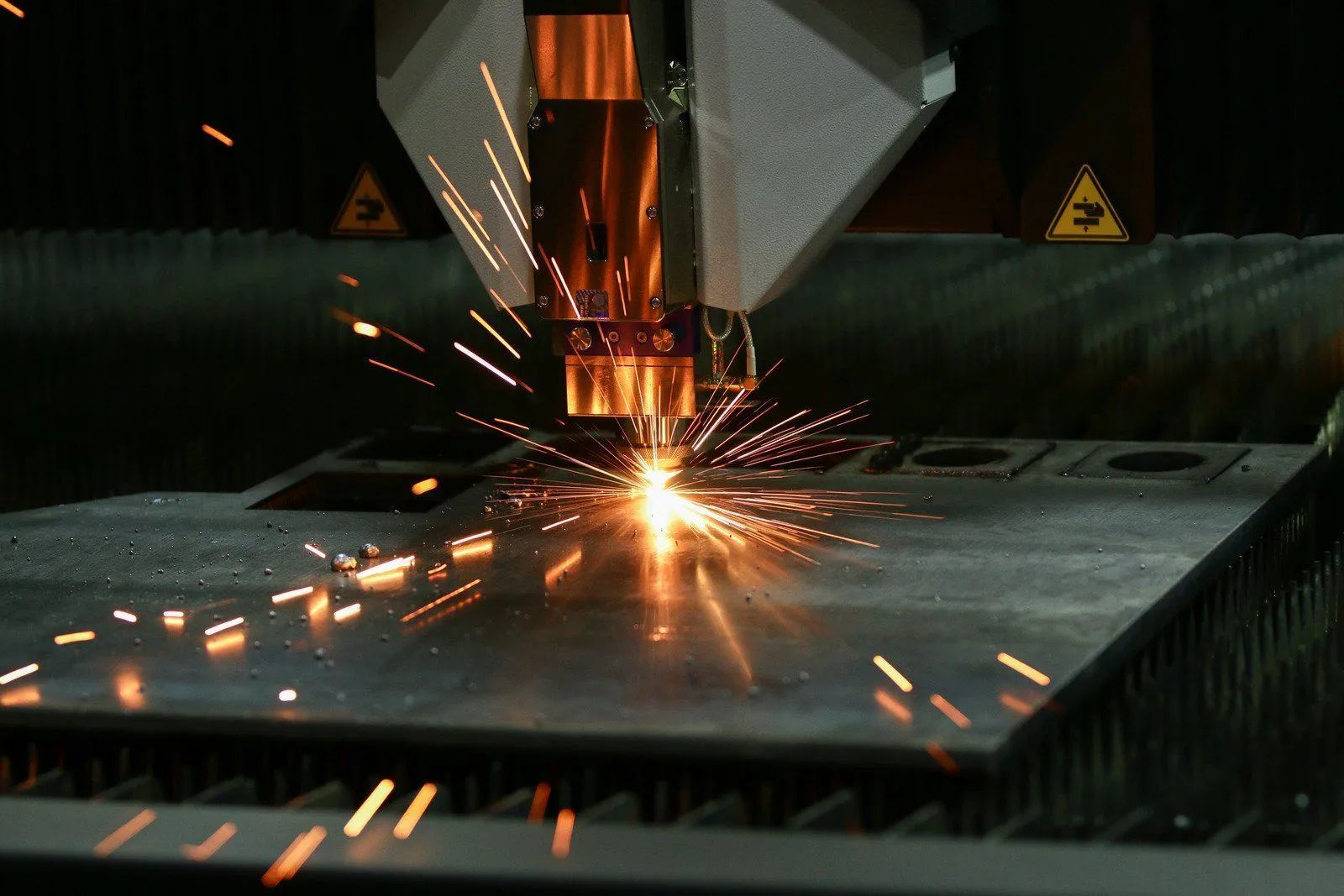

In any metal fabrication facility, airborne dust and fumes are more than just a nuisance—they are a serious health and safety concern. Welding, grinding, and cutting processes release fine particles and toxic fumes that can affect respiratory health, reduce productivity, and even pose long-term occupational hazards. These contaminants can accumulate quickly, creating not only health risks but also operational challenges, such as equipment malfunctions and poor visibility. Traditional ventilation often fails to remove these hazards effectively, leaving employees exposed to dangerous airborne substances. Implementing professional dust and fume collection systems is a critical step in creating a safer, cleaner work environment. These systems not only improve air quality but also enhance operational efficiency, reduce equipment wear, and help businesses comply with strict workplace safety regulations, making them an essential investment for any modern metal shop.

How Professional Dust and Fume Collection Systems Transform Workplace Safety

Professional dust and fume collection systems are engineered to capture and filter harmful particles at the source before they spread through the workspace. In metal fabrication, processes such as welding, cutting, and grinding generate fine dust and metal fumes that can be inhaled, leading to respiratory issues, allergic reactions, or even long-term lung damage. By integrating advanced filtration units, these systems efficiently remove contaminants, ensuring that employees breathe cleaner air throughout their shift.

Beyond health benefits, these systems significantly enhance workplace safety. Accumulated dust is highly combustible, creating potential fire and explosion hazards in metal workshops. A properly designed dust collection system minimizes this risk by continuously removing combustible particles from the environment, reducing the likelihood of dangerous incidents.

Another advantage of professional systems is their impact on operational efficiency. Cleaner air improves visibility and reduces equipment clogging, while also lowering maintenance costs. Employees can focus on their work without frequent interruptions caused by dust buildup or respiratory discomfort, leading to increased productivity and job satisfaction.

Furthermore, investing in dust and fume collection supports compliance with industry regulations. OSHA and other workplace safety authorities mandate proper ventilation and air quality standards in metalworking facilities. Using certified dust collection systems demonstrates a commitment to regulatory compliance and employee well-being, protecting the company from potential fines or legal liabilities.

Modern systems often include flexible ductwork, powerful extraction units, and multi-stage filtration, allowing customization to meet specific workshop needs. For metal fabricators, this means that even fine welding fumes and microscopic metal dust can be effectively captured and filtered, creating a safer, more comfortable, and more productive work environment for all employees.

Trusted Air Quality Solutions from Associated Metal Works

At Associated Metal Works, we understand that clean air is vital for a safe and efficient metal fabrication workspace. With over 40 years of experience in North Carolina, our team specializes in providing high-quality metal fabrication solutions that prioritize employee safety and operational excellence. By implementing professional dust and fume collection systems, we help businesses reduce health risks, prevent fire hazards, and maintain compliance with industry regulations. Trust Associated Metal Works to deliver expert solutions tailored to your workshop’s needs, ensuring a cleaner, safer, and more productive environment for your team every day.